The term “laser” is an acronym for Light Amplification by Stimulated Emission of Radiation. It is used in reference to devices that amplify a beam of light to produce a small but intense focal point. The technology finds application in a wide range of industrial and commercial operations. In the manufacturing sector, it is commonly used to mark and engrave components and assemblies for various purposes (e.g., indicating important information, adding aesthetic elements, or ensuring traceability).

While laser marking and laser engraving operate under the same basic principles, there are key differences between them that make them distinct processes. Below, we provide an overview of the laser marking process and the laser engraving process to help readers understand how they are different and when they should be used.

Overview of Laser Marking

Laser marking is a manufacturing process that uses a focused beam of light to permanently alter the surface of the workpiece. Unlike laser engraving, it changes the surface without removing material. It produces long-lasting high-contrast marks that can be easily read or scanned.

Types of Laser Marking Methods

There are many laser marking methods available. The four most commonly used are:

- Annealing

- Carbon migration

- Coloring

- Foaming

Advantages of Laser Marking

Compared to other marking methods, laser marking offers a number of advantages, such as:

- Higher marking accuracy/precision. The use of lasers enables manufacturers to target highly specific areas on the workpiece.

- Smaller environmental impact. The laser marking process produces much less waste since it does not require the removal of material from the workpiece to create the desired marks.

- Better compliance with industry regulations. The permanence and readability of laser-made markings make the laser marking process ideal for adding important information to manufactured components (e.g., barcodes, serial numbers, and trademark icons).

Applications of Laser Marking

The laser marking process is commonly used for:

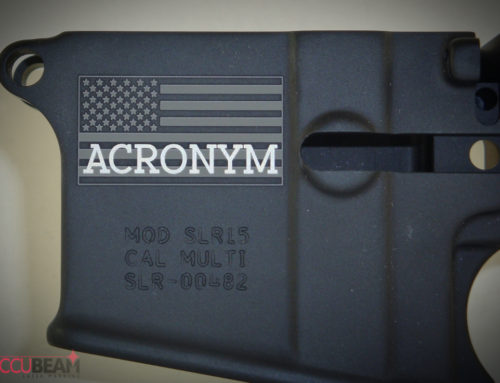

- Barcodes

- Date codes

- QR codes

- Serial numbers

- Part numbers

- Copyright/trademark icons

- Logos

Typical industries that use it to add the above elements to their parts and products include:

- Aerospace

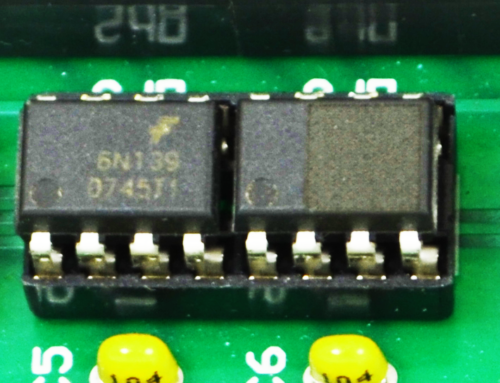

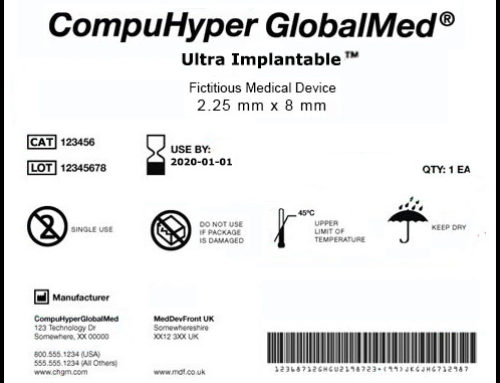

- Automotive

- Electronics

- Medical

- Semiconductor

Overview of Laser Engraving

Laser engraving is a manufacturing process that uses a focused beam of light to remove material from the workpiece to form the desired design (e.g., text or image). The resulting marks are durable and resistant to falsification.

Types of Laser Engraving Methods

The three main laser engraving methods are laser etching, laser engraving, and laser ablation. The key difference between etching and engraving and ablation is:

- Laser etching produces shallow marks

- Laser engraving produces deep marks that can withstand exposure to harsh operational or environmental conditions

- Laser ablation produces marks by removing surface coatings (e.g., painted or anodized layers) to expose underlying layers

Advantages of Laser Engraving

Laser engraving offers a variety of advantages over other marking processes, such as:

- Broader range of depths. Laser engraved marks can be made to varying depths, from shallow to deep.

- Better durability. The laser engraving process can produce marks that remain highly visible even after being exposed to harsh conditions.

- Greater marking speed. Laser engraving is the fastest way to produce laser-made markings.

Applications of Laser Engraving

The laser engraving process is used to mark parts and products for a variety of industries, including, but not limited to, the following:

- Aerospace

- Automotive

- Electronics

- Fine art

- Jewelry

- Medical

- Semiconductor

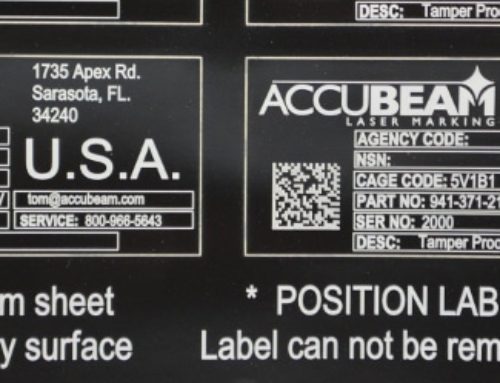

Learn More About Laser Marking and Engraving From Accubeam

Want additional information on the laser marking and laser engraving processes? Ask the experts at Accubeam! As a premier provider of laser marking, engraving, and cutting services, we can answer and address any questions you may have about these processes. To learn more about our laser capabilities, contact us today. To work with us on your next project, request a quote.