LASER ENGRAVING

What is Laser Engraving?

Laser engraving refers to the process of incising a design on the surface of a material using a beam of focused light. The light vaporizes or removes a layer of material, leaving a permanent cavity with higher contrast and a distinct feel from other regions of the surface. Skilled engineers can control the depth of the cavity and the amount of material removed to ensure quality engravings in any type of material.

Laser Engraving Technology

There are several different types of lasers depending on their source and wavelength. The commonly used types include UV, diode, fiber, and CO2 lasers. It’s important to note that laser engraving is different from laser marking. While laser engraving techniques, i.e., deep laser engraving, laser etching, and laser ablation, remove or vaporize the surface material, laser marking uses a laser to change the color of the material.

Here is a further explanation of laser engraving techniques:

Laser Etching and Deep Laser Engraving

Laser etching and deep laser engraving are similar types of laser engraving techniques, with the main difference being the depth of the engraving. In most cases, the shop you are working with and the material you want engraved are what determine which technique is right for you.

For example, engraving a cavity of 0.005″ in depth on aluminum is different than doing it on titanium, and both are different than stainless or tool steel. Deep engraving requires a skilled and experienced operator using the right laser. Most lasers produce heat, and too much heat on the material during deep engraving can cause damage and potentially destroy a part. As such, it’s important to choose the right laser engraving service provider.

Laser Ablation

Just like etching and deep engraving techniques, laser ablation involves vaporizing or removing surface material. The only difference is laser ablation removes a coating to expose either a different coating underneath or the bare surface material. Types of coatings that can be removed include powder coatings, anodized coatings, and paint.

Laser ablation is commonly used in applications such as:

- Powder-coated marine and boat parts

- TESA secure labels

- Anodized aluminum parts, plates, and ID tags

- Backlit buttons used in boats, cars, space vehicles, and aircraft

![]()

Advantages of Laser Engraving

Advantages of laser engraving include:

Precision and Accuracy

Because laser engraving utilizes a very thin, precise laser beam, the process is capable of achieving extremely high accuracy. This makes it ideal for engraving very detailed, intricate designs.

Material Versatility

Laser engraving is compatible with a wide range of materials in various thicknesses, including plastic, wood, metal, ceramic, glass, and more.

Time and Cost Efficiency

Businesses that need to produce high volumes of products quickly and efficiently will find laser engraving ideal. Depending on the design, material, and laser power, engravings can be completed in a matter of minutes.

Non-Contact Process

Since laser engraving is a non-contact process, there is no risk of material contamination, damage, or distortion of the component being engraved. This makes it a very safe and reliable process.

High-Volume Production

Laser engraving is ideal for companies seeking to produce a large number of engraved products. It can handle high-volume production runs while ensuring product consistency and quality.

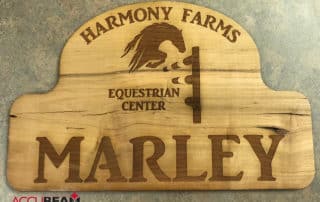

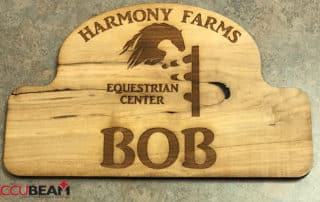

Personalization

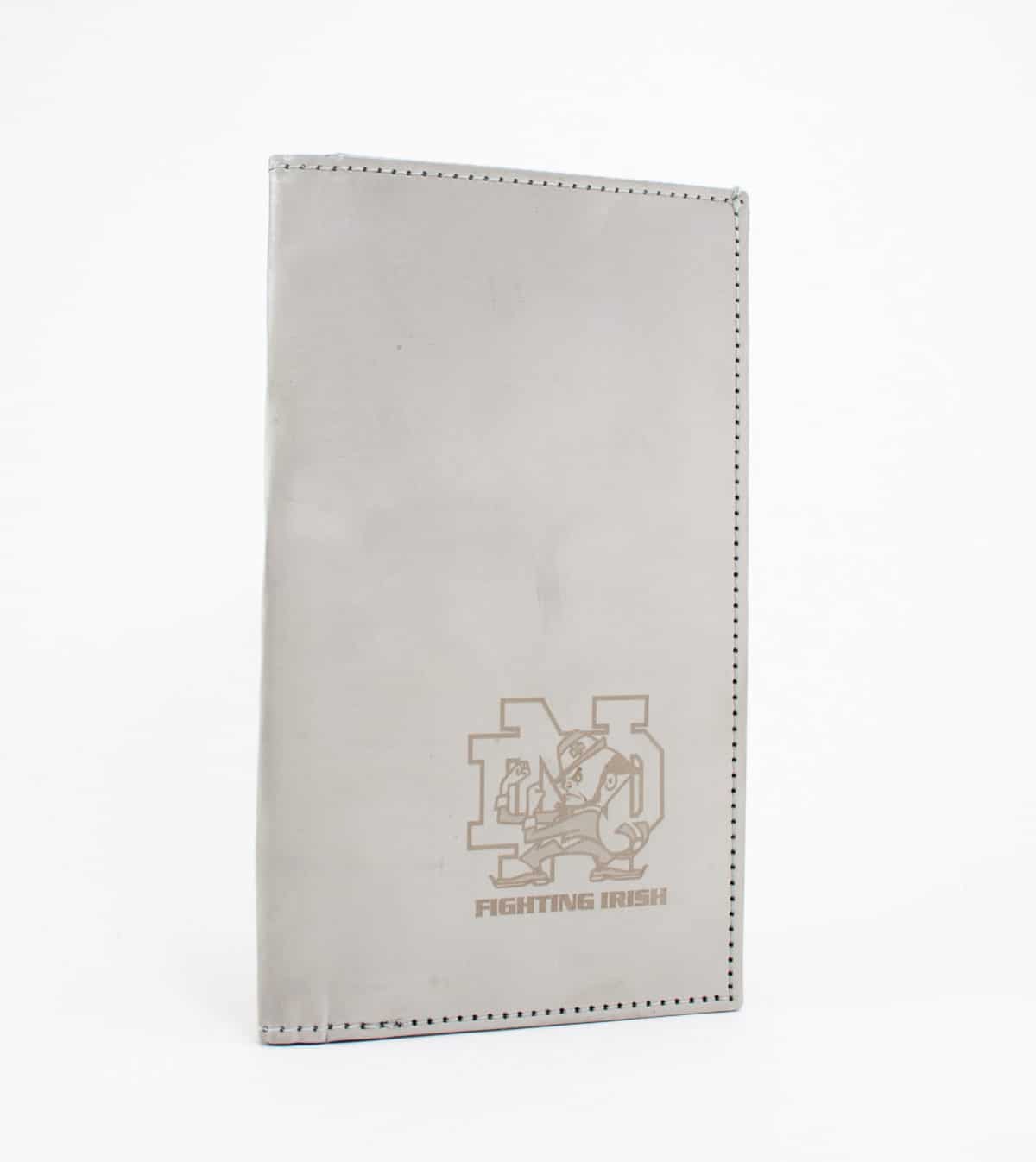

Laser engraving technology allows you to easily customize products and create personalized, one-of-a-kind products.

Minimal Maintenance

Compared to traditional engraving machines that necessitate regular upkeep, laser engraving machines require very minimal maintenance, resulting in lower costs.

Environmentally Friendly

Laser engraving offers a more environmentally friendly alternative to traditional engraving techniques. The process also generates less material waste, further improving its eco-friendliness.

Applications of Laser Engraving

Due to its several advantages, laser engraving is used across several applications and industries, including the following:

Aerospace

Laser engraving has become popular in the aerospace industry due to its ability to make parts easier to categorize and identify. Examples of laser engraving applications in this industry include creating labels and identification codes, marking panels and controls, serializing, regulatory marking, and more.

Automotive

The automotive industry uses laser engraving for regulatory marking, lot code tracking, serialization, product branding and labeling, bar codes, customization, and more. This cost-effective, eco-friendly, and fast process can be used on a variety of materials to create permanent markings on automotive components.

Electronics

The electronics industry uses laser engraving to add information and create permanent marks on parts and components such as circuit boards, panels, switches, sensors, chips, hard drive cases, and more.

Industrial

Different industries use laser engraving technology to mark injection molds, inserts, pins, dies, machinery parts, and other production equipment. Industrial laser marking can add branding to products and enables enhanced quality control within various facilities.

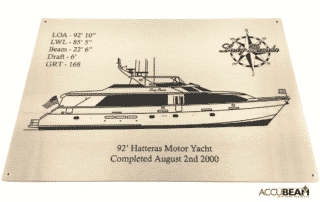

Marine

The marine industry uses laser engraving for regulatory marking, serialization, logo branding, and creating decorative designs. Laser engraving can engrave any material type used to make parts or components for commercial and recreational watercraft.

Medical

Common laser engraving applications in the medical industry include creating identification codes on medical devices and marking surgical instruments.

Military

Laser engraving is ideal for adding permanent marks on military equipment and parts that must withstand harsh conditions. Examples of these parts and components include knives, firearms, military helicopters, vehicles, and equipment. Additionally, military laser engraving is used to create identification codes and custom designs on equipment.

Promotional

Many companies use laser engraving to add branding information to promotional products. Common applications for promotional laser engraving include pens, USB drives, flashlights, pocket knives, and keychains with custom designs.

Drinkware

Laser engraving can be used to add custom designs, branding, and other graphics to various types of drinkware, such as mugs, canteens, and tumblers.

3D Photo Engraving, Jewelry, Artwork

Another popular application of laser engraving is creating designs on artwork, jewelry, and 3D photos. Artists and jewelers use this technology to design unique pieces made from various materials.

Custom Gun and Firearm Engraving

Laser engraving can be used by gun enthusiasts and firearm manufacturers to add customized aspects to guns and accessories. This can include intricate designs, personalized text, and more.

Laser Engraving Services and Capabilities

At Accubeam, we use UV, CO2, fiber, and YAG lasers to engrave, etch, mark, and cut an extensive range of materials, including plastics, glass, rubber, metal, wood, and more. Our services and capabilities include:

- Specialized tooling. We have the necessary equipment and knowledge to design and build any specialized tooling for handling unique parts and automating large production runs.

- Deep engraving. We have the skills and capabilities to efficiently and quickly engrave depths up to 0.030″ on various materials.

- Volume. With our facilities and tooling capabilities, Accubeam can accommodate both low and high production volumes.

- Managed inventory and drop shipping. At Accubeam, we can manage inventory for recurring product orders. We’ll process and drop ship orders to your customers with your shipping documents.

Accubeam provides personalized, high-quality, and cost-effective laser engraving services to meet the needs of various industries and applications. For more information about our capabilities, or to get started on your custom laser engraving solution, contact us or request a quote today.