Laser Cutting & Engraving for the Medical Industry

Manufacturers must adhere to the highest standards when cutting and engraving parts for medical applications. Everything from the processes used to the materials they produce goods with must follow medical and industrial regulations, so end-users and patients can truly benefit from the technology. Along with precisely cutting and shaping components to fit within specific product design parameters, customers in the medical sector may need to engrave custom and sequential numbers into products for future tracking needs.

Accubeam has vast experience providing laser cutting and engraving services that help organizations comply with stringent manufacturing standards and traceability protocols. We can permanently carve legible alphanumeric codes into products and components. These marks outlast high-temperature sterilization and cleaning cycles. Our engraving machines can also process components for small assemblies and complex medical devices.

Learn more about how laser cutting and laser engraving for medical organizations can streamline your production and guarantee better traceability.

Laser Cutting for the Medical Industry

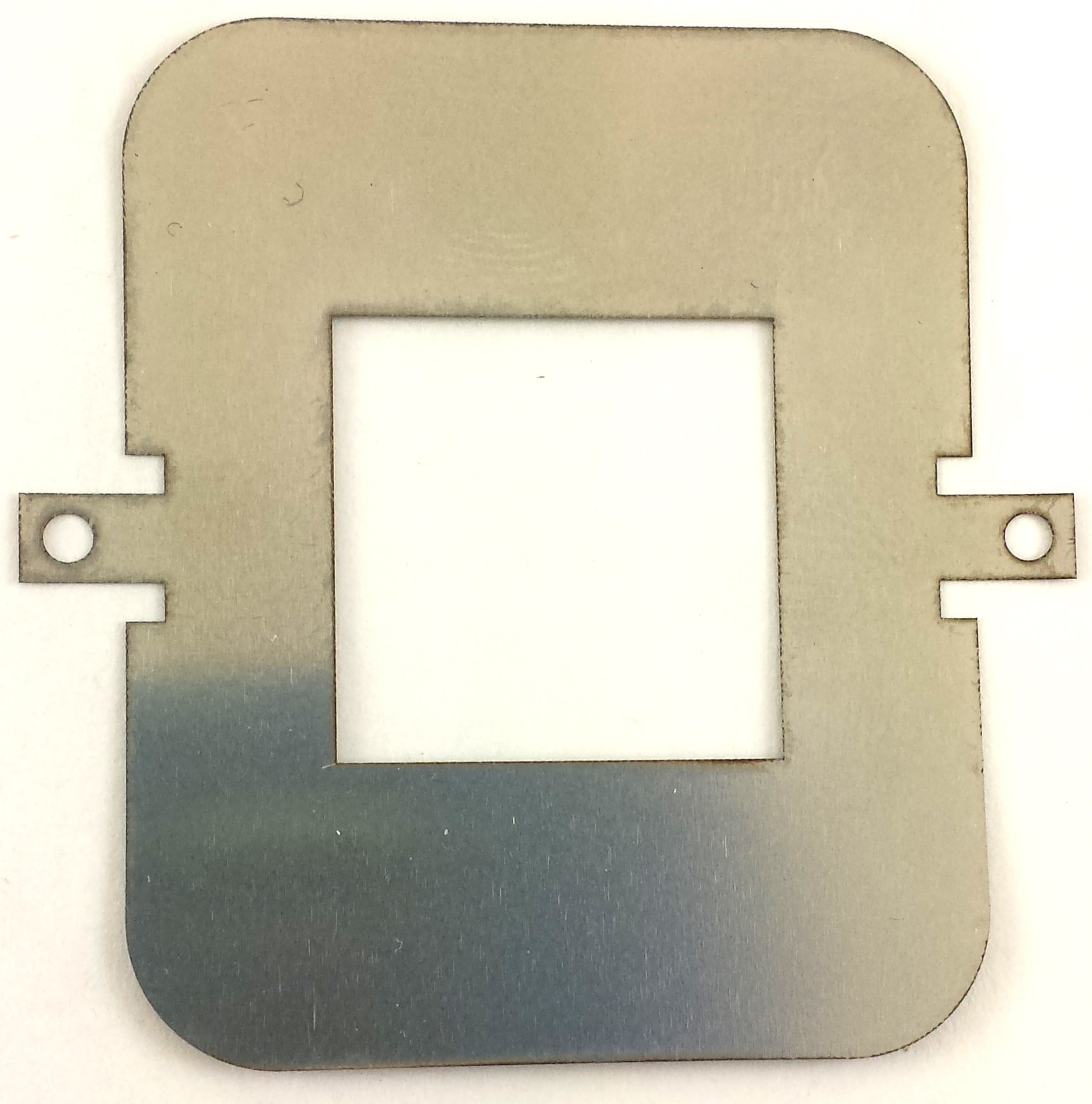

Accubeam’s laser-cutting techniques outpace other machining and cutting processes used to process medical goods. Our CNC laser-cutting machines replicate design parameters faithfully, so every component has the right shape and dimension while meeting tight tolerances. We can use these machines to cut through or engrave material with very little material waste, leaving behind crisp, clear edges and engravings.

Utilizing advanced laser cutting and laser drilling machines like CO2 lasers, fiber lasers, Nd:YAG lasers, and UV lasers, our technicians can produce high-quality components and engrave each one with identifying details, serial numbers, and other codes. Other common applications that rely on our precise laser-cutting medical production capabilities include components used in surgical devices and tools, parts for wearable medical devices, goods for diagnostic testing processes, and more. Our clients choose laser cutting for these processes because it’s clean, does not compromise the structural integrity of the material, and does not introduce contaminants.

Additional benefits of Accubeam’s laser cutting and laser engraving medical manufacturing services include:

High Precision

Our lasers are incredibly precise, focusing the light to a very narrow point for fine engraving and cutting. Combined with our cutting-edge CNC machinery, which translates even the most complex designs into clear instructions and directs the laser to complete each cut, our laser engraving and cutting work offers more accurate results than ever.

Cost-Effectiveness and Speed

CNC laser engraving is automated, fast, and does not require additional finishing and cleaning stages, making our process a cost-effective option for customers. Accubeam can quickly complete low-volume and high-volume orders with minimal delays. We can also provide custom or sequential engraving to ensure compliance with traceability requirements.

Customization

Create more innovative products and cleanly mark all of your products with Accubeam’s numerous laser-cutting options. Based on your industry requirements, unique demands for your product, and branding norms, you can have any design, serial number, or tracking codes engraved onto your components. Lasers can also cut intricate shapes from sheet metal or other substrates, and drill holes through the interior of the piece for fastening or assembly, leaving behind clean, crisp edges.

Versatility

Accubeam offers laser cutting and engraving for a wide range of different product materials. Our lasers are compatible with metals, glass, plastics, and composite materials, so you can rely on laser cutting for most stages of production without having to switch between tools or service providers at each step.

Increased Capacity to Scale Up Production

We utilize our vast in-house engineering expertise to effectively handle larger production runs, quickly scaling up production to meet demand. CNC laser cutting doesn’t require tooling production or high manual labor costs. Our machines can work through cycle after cycle without losing accuracy or getting tired. The scalability of our services also means you can quickly ramp up production once you secure new markets.

Laser Engraving for the Medical Industry

Product marking and identification services are a key element in many medical applications. Our laser engraving services for medical components include the following options:

- Bar codes

- Nameplates

- Logos

- Product identification codes

- Serial numbers, as well as lot and date coding with sequential numbering

Laser-engraved identifying details help guarantee better traceability, as the marks are permanent and outlast standard wear, sterilization cycles, and cleaning. The engravings themselves won’t fade or corrode, which also helps protect patients and limit risk factors associated with infection or contamination.

Current applications Accubeam can complete laser engravings for include:

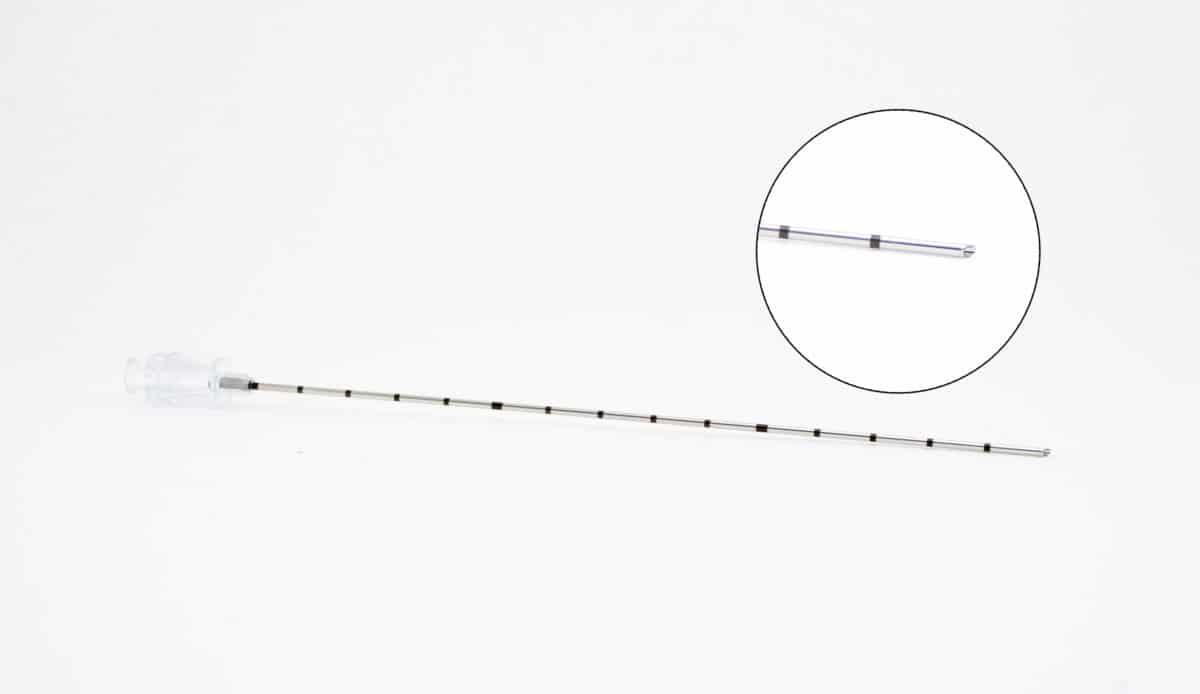

- Medical and surgical components

- Bone screw identification markers

- Instrument panels

- Sensors and instrumentation

- Mold cavity, core, and pin engravings

Learn More About Accubeam’s Laser Cutting and Engraving Services

Accubeam is committed to providing quality laser cutting and engraving services. We can produce precise shapes and designs in steel, stainless steel, carbon fiber, wood, fabrics, and more. We can also create permanent identifying marks that won’t adversely impact the quality or utility of your products. Per our UDI certification, we include UDIs for device labels, packaging, and component services and submit the relevant device information to the Global Unique Device Identification Database (GUIDID).

We serve medical, aerospace, industrial, military, and electronics manufacturers with comprehensive, scalable laser cutting services and engraving services. Reach out today to learn more about our full capabilities or request a quote on our site to get started on your order.