Laser Cutting Plastic & Synthetics

![]()

Accubeam Laser offers contract Laser Cutting Plastic Services to produce a wide array of parts and components from all types of Plastics and Synthetic Materials including; Mylar, Acrylic, Delrin, ABS, PE, PP, all Poly types, silicone, foam rubber and much more.

Accubeam has the unique ability to Laser Cut and Laser Engrave single, multiple or laminated sheets of material in a single process, producing exceptional quality products that are cost effective.

We provide different types of Laser Cutting Plastic processes applied based on the material type and requirements, Flame, Fusion, Sublimation and Laser Drilling, each can be assisted with inert gases to boost the energy or ensure the edges are oxide free.

Benefits of Laser Cutting Plastic

Laser cutting plastic creates intricate details cut to close tolerances. Other processes cannot achieve the same degree of precision. CNC programming flexibility allows laser users to change component designs quickly and effectively. The process requires virtually no hard tooling.

Accubeam’s experiences in programming and process control minimizes part variation to hold tighter tolerances on plastics and synthetic materials.

Laser Cutting Plastic Applications

The potential applications for laser engraved and cut components are varied and include:

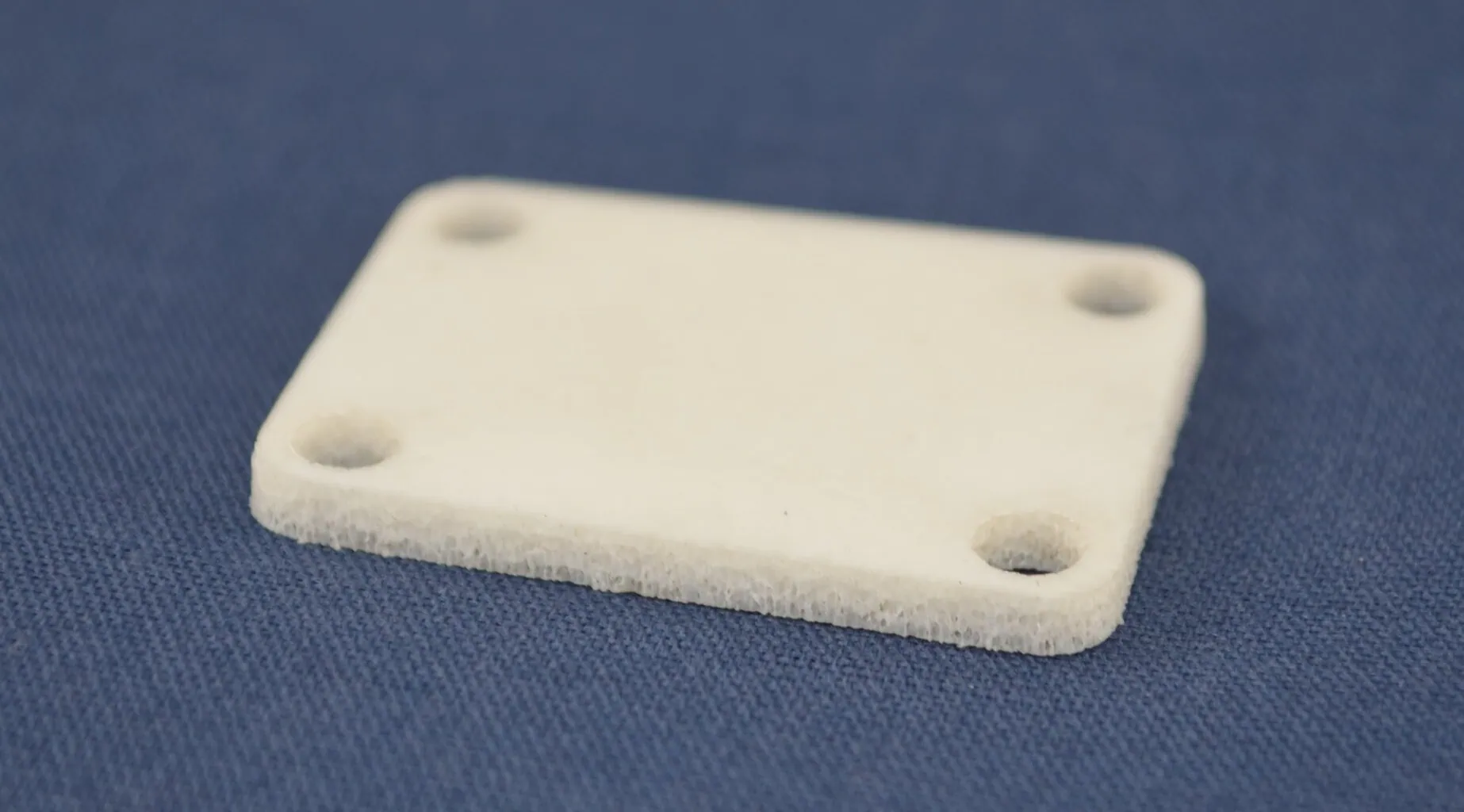

- Nameplates

- Sign-making

- Control panels

- Displays

- Polished-edge acrylic

- Gaskets, seals, shims

- IT tags and plates

We help our customers tailor products like these to meet their applications’ unique requirements.

| Specifications | |

|---|---|

| Laser Type | (3) CO2 Lasers w Gas Assist Advanced vision system for cut registrations, vision targets and auto-scaling |

| Materials | Mylar (PET), Acrylic, Delrin, ABS, PE, PP, Olephins, Polyimide, Polycarbonate,Polyester, Polystyrene, Polyurethane Urethanes, Aramid,, Nylon Flexible Circuits – Polyester & Polyimide (Kapton) Fiberglass, Phenolic & Solid Surface Material (Corian) Kevlar, Polyester Fabrics & Velcro Aerospace – Insulation, reflective wraps |

| Cutting Thickness | Acrylic .25″ |

| Working Range – x y | x-48″ y-36″ |

| Tolerance | +/- .002″ |

| Gas | Air Assist |

| Drawing Types | .dxf .ai .dwg .hpgl .jpg .bmp .tif & Gerber |

| Secondary Operations | Blanchard Grinding Surface Grinding 3 Axis CNC |

| Industry Focus | Aerospace Medical Military Automotive Marine Industrial Electronics Signage Furniture |

Common Plastic Laser Cutting Materials

We supply our clients with a selection of materials, including:

- Acrylics

- Plexiglass

- HDPE

- HDPP

- Mylar (PET)

- Acrylic

- Delrin

- ABS

- PE

- PP

- Olephins

- Polyimide

- Polycarbonate

- Polyester

- Polystyrene

- Polyurethane urethanes

- Aramid

- Nylon

- Flexible circuits—polyester & polyimide (Kapton)

- Fiberglass, phenolic & solid surface material (Corian)

- Kevlar, polyester fabrics, and Velcro

- Insulation and reflective wraps (aerospace)

Which Materials Can’t Be Used With Laser Cutting?

Some materials are incompatible with laser cutting. Any material that contains chlorine, for example, cannot be used with laser cutting. This includes PVC and vinyl.

Laser Cutting Plastic Specifications

- Laser type: (3) CO2 lasers w/ Gas Assist Advanced vision system for cut vision targets and auto-scaling

- Cutting thickness: Acrylic 1”

- Working range– x y z: x-50” y-50” z-9.5”

- Tolerance: +/- .002”

- Gas: Oxygen and nitrogen

- Drawing types: .dfx .ai .dwg .hpgl .jpg .bmp .tif & Gerber

- Secondary operations: Blanchard grinding, surface grinding, 3-axis CNC

General Plastic Laser System Considerations

- Max platform size: 48 x 48

- Laser sources for cutting services: CO2, , UV

Why Choose Accubeam?

At Accubeam, our team prioritizes diligent inspection and quality control. Our clients rely on us for projects with tight tolerances because they know that we hold to each one. We leverage over 40 years of combined industry experience to produce high-quality components.

If your next project requires plastic laser cutting services, contact us today or request a free quote for more information. For a comprehensive list of Laser Cutting Plastic capabilities refer to our Specifications Table below.