Laser Cutting Metal Services

![]()

At Accubeam Laser, we offer contract laser cutting services for a wide range of ferrous and non-ferrous metals. As a production method, laser cutting is effective at creating highly precise and accurate parts from sheet metal. The process uses a high-powered laser beam to heat, melt, and vaporize specific sections of the workpiece to produce the design of a part or component.

What Is Laser Cutting Metal?

The laser cutting process uses the heat from computer-controlled, concentrated beams of light to quickly melt various metal materials and alloys. This highly efficient, subtractive manufacturing technique is actually the combination of two processes. First, as the metal absorbs the beam, its energy converts to the heat that successfully creates precise cuts in the material. Next, a pressurized stream of gas clears away any remaining vaporized or molten metal from the part surface.

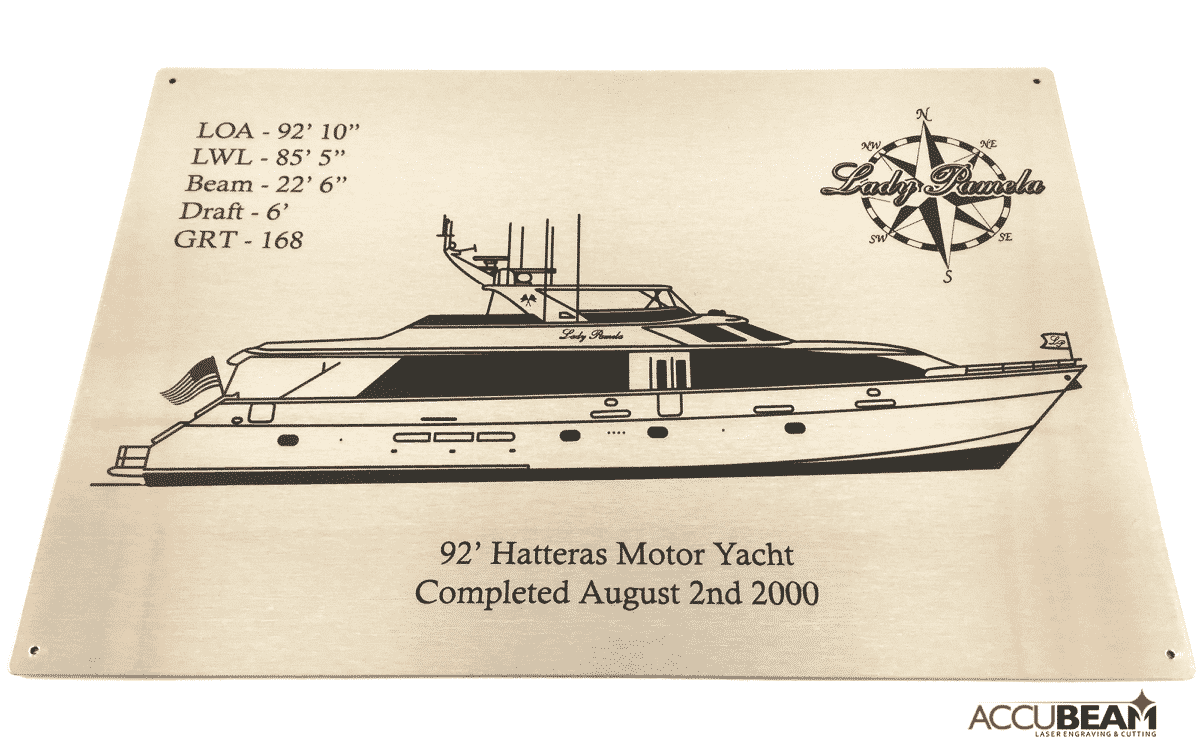

The technique achieves sharp, clean cuts with minimal material waste. Producing parts with extremely smooth edges, laser cutting reduces the need for finishing processes due to a lack of heat deformation. This has the side benefit of making laser metal cutting services particularly effective for high-volume metal parts manufacturing. Accubeam’s custom laser cutting metal services allow us to produce a variety of parts and structural shapes with tight tolerance windows, ranging from vehicle bodies and engine frames to aircraft components and surgical tools.

Our Laser Cutting Metal Capabilities

Our laser-cutting equipment accommodates a variety of metals to meet the varying needs of our customers. The metals for which we have the capacity for laser cutting include:

- Aluminum

- Brass

- Bronze

- Steel and steel alloys (e.g., carbon, stainless, mild, spring, and tool)

- Titanium

- Titanium & Stainless Steel Mesh

For these metals, we offer the following laser-cutting capabilities:

- Assist gases: Oxygen and Nitrogen

- XYZ working range: 48 inches (X) by 48 inches (Y) by 3.5 inches (Z)

- Cutting thicknesses: Mild Steel – .375 inches; Aluminum – .25 inches; Copper and Brass – .25 inches; Titanium – .125 inches

- Tolerance: +/- .002 inches

- Supported drawing types: .dxf, .ai, .dwg, .hpgl, .jpg, .bmp, .tif, and Gerber

For a comprehensive list of laser cutting metal capabilities refer to our Specifications Table below.

We provide different types of laser cutting metal processes based on the material type and requirements. For flame, fusion, sublimation, and laser drilling, each can be assisted with inert gases to boost the energy or ensure the edges are oxide free.

Here at Accubeam we have extensive experience laser cutting a wide array of materials and parts for all industries to provide exacting solutions that meet or exceed our customer’s needs and specifications. Laser cutting is computer driven process, leading to accurate and repeatable cutting of parts where holding tolerances is critical.

| Specifications | |

|---|---|

| Laser Type |

4000 Watt Fiber Laser Cutting System Advanced vision systems for cut registrations, Gas Assist Cutting for Clean Edges |

| Materials | Stainless Steel Sheet Metal Mild Steel Spring Steel Tool Steel Aluminum Titanium Brass Bronze |

| Cutting Thickness | Mild Steel – .375″ Stainless Steel – .25″ Aluminum – .25″ Copper & Brass – .25″ Titanium – .125″ |

| Working Range – x y | x-48″ y-48″ |

| Tolerance | +/- .002″ |

| Gas | Oxygen & Nitrogen |

| Drawing Types | .dxf .ai .dwg .hpgl .jpg .bmp .tif & Gerber |

| Secondary Operations | Blanchard Grinding Surface Grinding 3 Axis CNC |

| Industry Focus | Aerospace Medical Military Automotive Marine Industrial Electronics Signage Furniture |

Laser Cutting Metal Industries & Applications

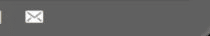

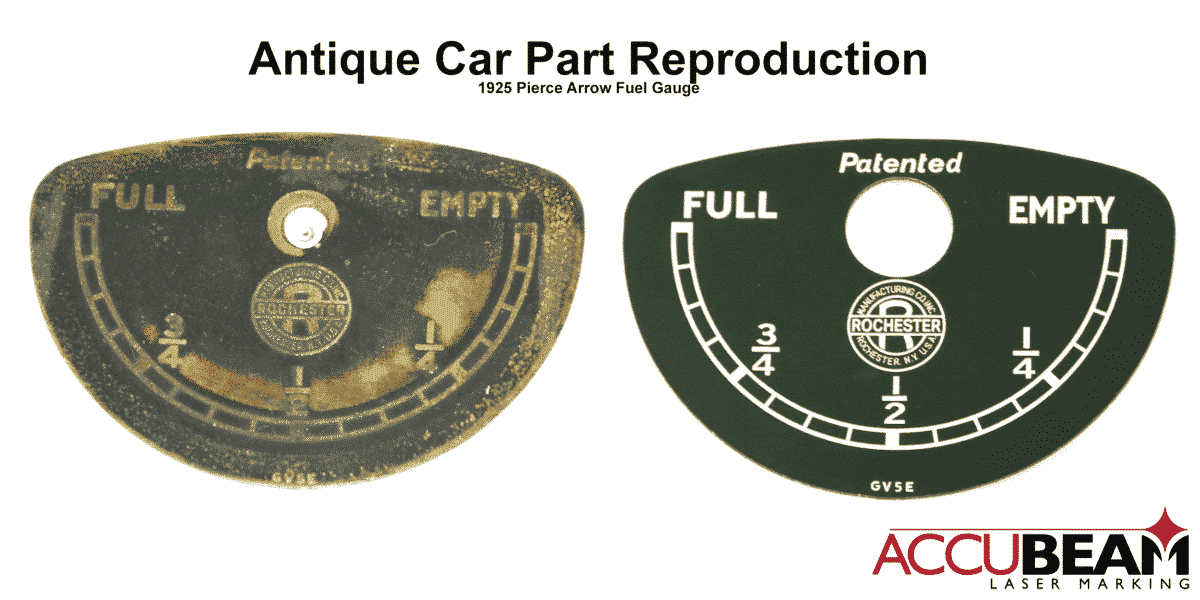

Our custom laser cutting metal services support some of the largest and most technically precise industries in the world. In addition to generating accurate cuts, laser cutting also has applications for engraving components or marking them with serial numbers, branding information, and related identification information, all as part of a single process.

Laser cutting metal is an ideal manufacturing method for the following markets:

- Aerospace. The aerospace industry requires high production quality for various aircraft and space exploration components, including products like tooling and fixture parts, wing fasteners, and end effectors. Given the mission-critical nature of aerospace components, laser cutting is an ideal fit for the industry for its optimal quality control.

- Military. Laser cutting can also generate rugged military parts and equipment with precision, including products like high-impact armor plating for military vehicles like Humvees as well as various other heavy-duty defense components. It’s applicable for land, marine, and air projects. Like the aerospace industry, parts for this sector must comply with strict quality standards like MIL-SPEC, and laser cutting has the ability to adhere to such regulations.

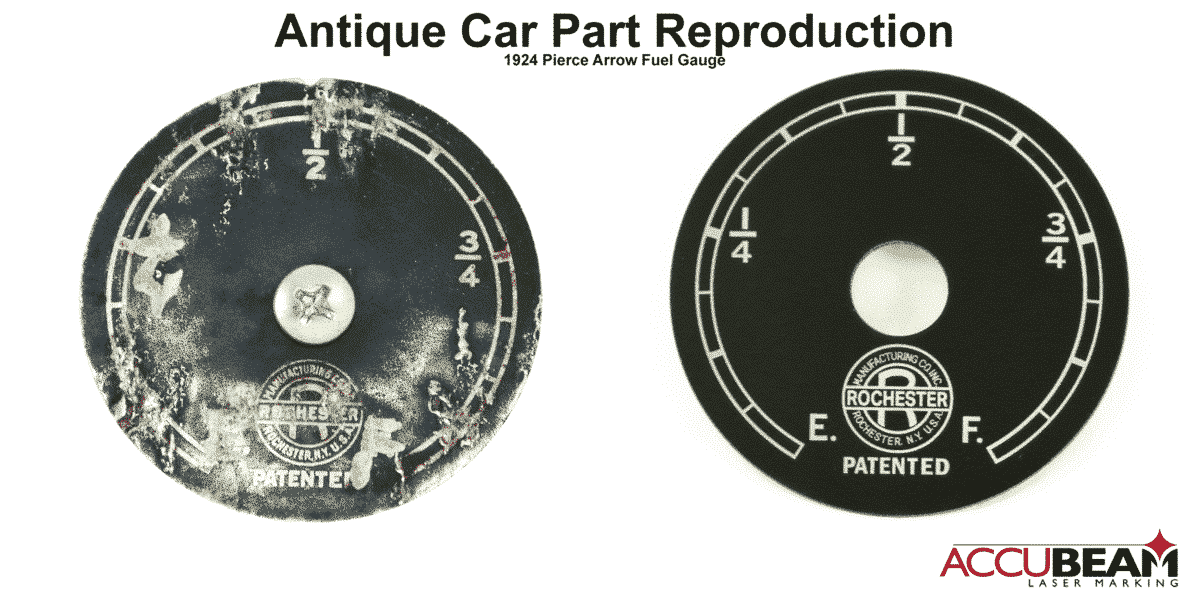

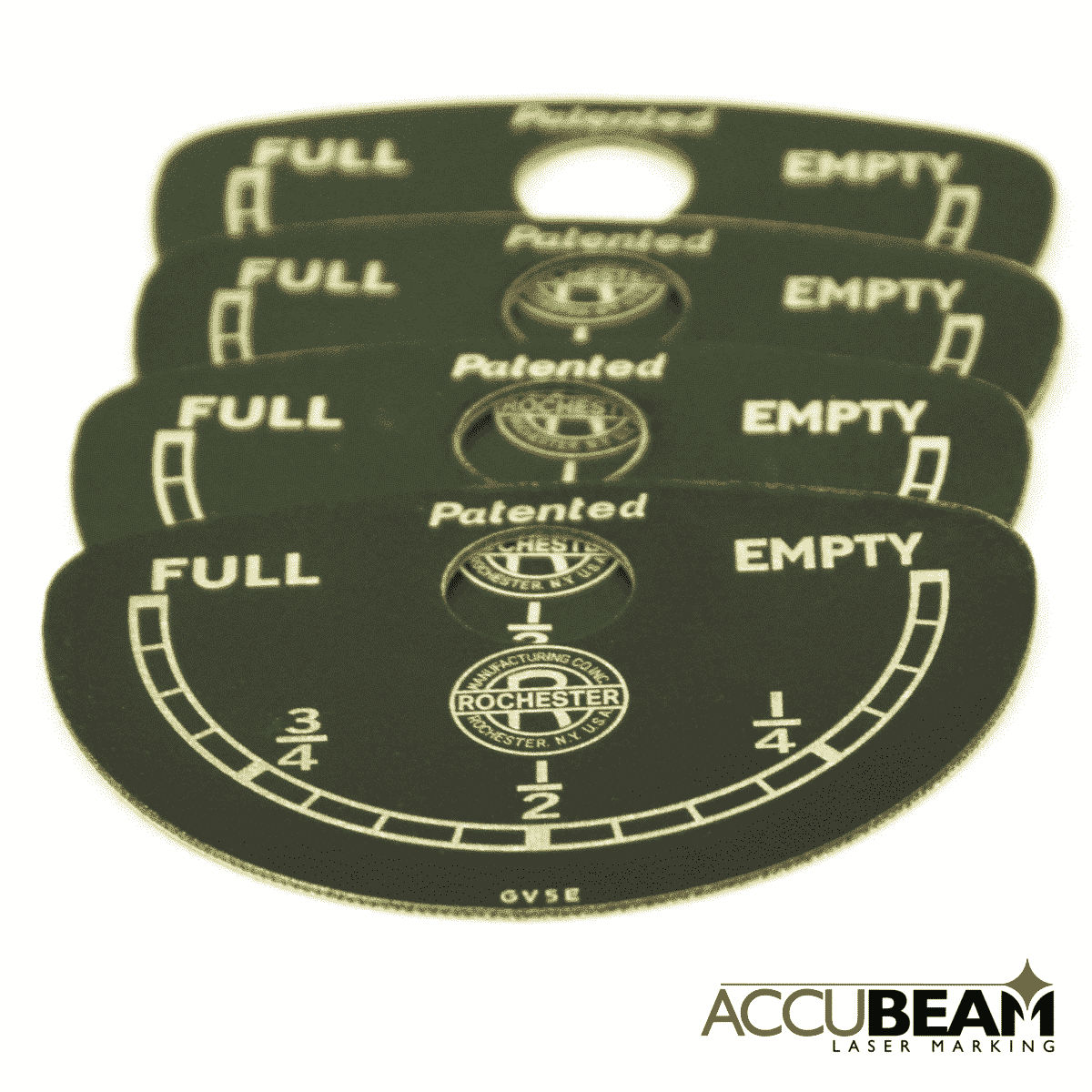

- Automotive. In automotive manufacturing, laser metal cutting services are a preferred, scalable method for producing uniform metal parts in high volumes. However, they can also play a part in the manufacturing process for custom cars, enabling highly detailed and accurate work. Because laser cutting is compatible with a wide range of materials, it also meets the need for versatility that automotive manufacturers depend on.

Laser Cutting Metal Advantages

Using laser cutting as your production method for generating metal parts offers numerous benefits. Some of these include:

- High product quality

- Clean, precise cuts

- Reduced deformation and burring for minimal part finishing

- Affordability

- Rapid production and shorter turn times

- Minimized downtime for streamlined production

- Part uniformity and repeatability

- Material and design versatility

- Compatibility with automation solutions like CNC machining equipment and robotic systems

- Reduced material waste and energy consumption

- Contactless processing for safer and less labor-intensive manufacturing

Even when a product has a complex configuration, requires intricate cuts, or you need to make design alterations, laser cutting metal is a highly efficient process that allows for high production speeds and throughput without sacrificing quality or close tolerances. It can also handle high-strength materials and superalloys that some other manufacturing methods can’t, such as steel and titanium superalloys.

Why Choose Accubeam?

By choosing us as their laser cutting metal service provider, our customers experience a number of advantages over our competitors, including:

- Specialized tooling. We have the experience and equipment necessary to create specialized tooling for custom or unique part or component production operations, including automating large production runs to meet customer demands.

- Deep engraving. Our team can produce engravings to depths in excess of 0.030 inches on any material with high efficiency and fast lead times.

- Volume production versatility. Regardless of whether a customer needs short or full-scale, large production runs, we can accommodate their production needs.

- Managed inventory and drop shipping. We offer in-house inventory management services for recurring product orders, including pulling, processing, and drop shipping.

Laser Cutting Metal Services From Accubeam

As an industry leader in innovative tooling and processes, Accubeam understands how to offer customers the greatest product value. We ensure customers always receive the highest quality products and superior customer service by leveraging our over 15 years of experience in laser cutting and committing ourselves fully to honesty and transparency. Whether a customer needs a short run or full-scale production run, no job is too small or too large for our expert team.

To learn more about our laser cutting capabilities, see our laser cutting portfolio. For additional information or to speak with one of our experts about your project specifications, contact us or request a quote today. Our sales teams located in Sarasota and Orlando look forward to serving your laser cutting metal needs.