LASER CUTTING

Our Custom Process

At Accubeam, we have the experience and equipment to laser cut 2D parts:

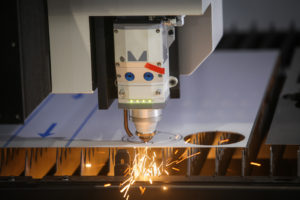

2D Laser Cutting

Laser cutting tools are commonly used to cut precise designs and features into two-dimensional substrates, such as fabrics, paper, and thin sheets of harder substrates. By employing lasers, we reduce the processing time required for cutting single layers, stacked substrates, and laminated substrates, making the overall production process faster and more cost-efficient.

Laser Cutting Methods

Fabricators employ different laser cutting processes depending on the material and thickness of their workpiece. While the basic principles of the process remain relatively the same—i.e., using a focused beam to melt the substrate and an assist gas to facilitate the cutting process—there are distinct differences between the variants. Some of the most types we employ are:

- Flame cutting:This process uses oxygen to remove molten material from the kerf. The oxygen reacts to the substrate material, creating an exothermic reaction that adds energy (in the form of heat) and accelerates the cutting process.

- Fusion cutting:In contrast to the flame cutting method, fusion cutting uses assist gases chosen specifically for their lack of reactivity to the substrate.

- Sublimation: In sublimation laser cutting, the laser heats the substrate material to the point of vaporization (i.e., sublimation) and the inert assist gas blows away excess material.

- Laser drilling: Laser drilling is a process that employs laser beam pulses to produce holes through a workpiece.

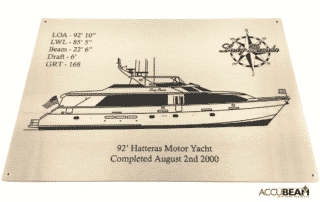

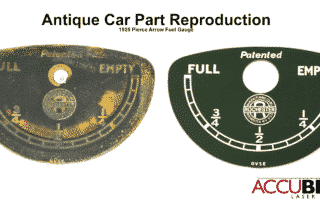

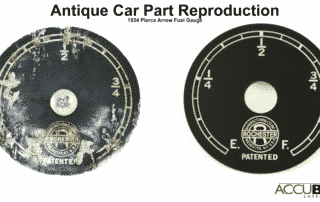

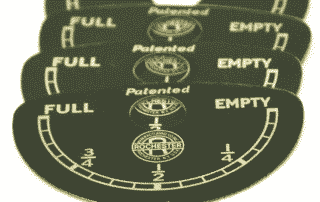

Laser Cutting Metals

At Accubeam, we provide cutting capabilities for all types of metal substrates, including laser cutting steel, aluminum, titanium, brass, and bronze, in working ranges up to 50 inches x 50 inches x 9.5 inches. Our laser cutting equipment offers tolerances of ±0.002 inches for precise metal designs.

Depending on the metal, we can handle different thicknesses and apply different laser cutting methods, including flame cutting, fusion cutting, sublimation cutting, and laser drilling, to create a durable and consistent finish along the cut edge.

Steel and Stainless Steel

For steel materials, our laser cutting capabilities range from 0.125 inch cuts in stainless steel to 0.25 inch cuts in mild steel. While these materials are traditionally cut with oxygen-assisted lasers, nitrogen-assisted processes are becoming increasingly popular due to the reduced risk of oxidation and discoloration. However, thicker steel sheets require more time to cut; therefore, the faster oxygen-assisted laser cutting may be more cost-effective in certain applications. With this consideration in mind, both flame and fusion laser cutting are ideal processes for cutting steel or stainless steel sheets and plates.

Aluminum

Aluminum substrates are typically cut with nitrogen-assisted lasers. The use of nitrogen assist gases displaces oxygen from around the cut edge, preventing corrosion and removing the need for additional cleaning and finishing processes after the laser cutting.

Our laser cutting equipment can cut aluminum materials up to 0.125 inch in thickness.

Titanium

Titanium is a durable metal that is suitable for laser cutting high quality, precision parts for the medical, pharmaceutical, and aerospace industries. One of the significant advantages of laser cutting titanium sheets is the ability to produce intricate designs, including hole patterns with a smaller diameter than the thickness of the sheet.

Our laser cutting capabilities allow us to cut titanium in thicknesses up to 0.030 inches.

Brass

Similar to steel and steel alloys, brass substrates are laser cut with nitrogen or oxygen-assisted laser cutting equipment. Although oxygen speeds up the process, nitrogen-assisted laser cutting generally creates a smaller kerf no thicker than 0.040 inch (compared to 0.060 inch by oxygen-assisted lasers). Laser cut brass parts are used across several industries.

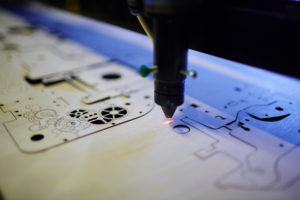

Laser Cutting Plastics and Synthetics

Laser cutting is ideal for cutting plastics and synthetics as the heated affected zone (HAZ) is relatively small compared to other cutting methods. This characteristic allows laser cutting to produce higher quality edges and minimize the need for additional finishing operations.

At Accubeam, we employ flame cutting, fusion cutting, sublimation, and laser drilling operations to process a variety of plastic and synthetic substrates—including acrylic, silicone, foam, vinyl, and carbon fiber—in working ranges up to 50 inches x 50 inches x 9.5 inches and tolerances of ±0.002 inches.

Acrylic

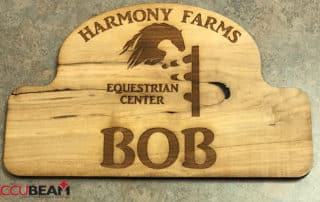

Cast and extruded acrylic materials are laser cut to remove excess material or produce precise designs into the body of the substrate. Laser cut acrylic parts are commonly used in signage and decorative applications as letters, images, and custom designs.

Silicone

Laser cutting silicone rubbers and foams results in minimal damage to the material. The process is often used to create holes and cutouts in silicone components to allow for easier assembly.

Foam

Foam is a soft polymer material with cellular pockets formed by trapped gas. As the material is easily damaged and compressed, laser cutting foam is the ideal processes to use when fabricating components. Laser cut foam is typically used as models or packing materials. In addition, laser engraving is available.

Vinyl

Laser cutting vinyl produces precisely cut graphics and vinyl-covered substrates without damaging the material. This process is ideal for fabricating marketing and display materials, such as signage, for commercial applications.

Carbon Fiber

Laser cutting carbon fiber reinforced polymers (CFRPs) produces higher quality products when compared to other mechanical cutting methods. In both laser engraving and laser cutting, the processes seal the fibers of the substrate, producing cleaner edges.

In addition to the above-mentioned materials, we can process several other plastics and synthetics, including:

- Acrylonitrile butadiene styrene (ABS)

- Aramid

- Delrin

- Nylon

- Polycarbonate

- Polyester

- Polyethylene (PE)

- Polyimide

- Polypropylene (PP)

- Polystyrene

- Polyurethane

- Urethanes

- Velcro

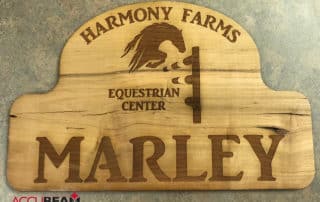

Laser Cutting Wood and Paper

Laser cutting is ideal for flexible materials like wood and paper as the process does not apply mechanical force to the workpiece. This process characteristic reduces the risk of warping in the final part or product.

Our flame cutting, fusion cutting, sublimation, and laser drilling services are used to process a wide variety of wood and paper products, including wood board, veneer, MDF, plywood, cardboard, and adhesive labels. We can laser cut and engrave single-sheet and multi-sheet stacks of wood and paper substrates in sizes up to 50 inches x 50 inches x 9.5 inches and thicknesses up to 1 inch. Our cutting tolerances are as tight as ±0.002 inch.

Laser Cutting Organics and Fabrics

Laser cutting creates precise designs and shapes in fabric (e.g., cotton, polyester, and Kevlar) and organic (e.g., leather, cork, and wax) material. Additionally, the process produces high quality edge finishes with minimal material waste.

At Accubeam, we provide a variety of laser cutting and engraving services for fabric and organic substrates, including flame cutting, fusion cutting, sublimation, and laser drilling. These processes can cut materials up to 50 inches x 50 inches x 9.5 inches in any thickness with tolerances as tight as ±0.002 inch.

Leather

Leather goods are designed and constructed to withstand a lot of wear and tear. The laser cutting process produces edges that do not fray or break down, increasing the durability of laser cut leather parts. Additionally, laser cutting and engraving allows fabricators to add intricate design and features, such as smaller belt buckle holes and decorative surface finishes.

Fabric Laser Cutting

The laser cutting process seals fabric edges as it cuts, preventing fraying, loose threads, and unraveling edges. This process characteristic allows fabricators, such as Accubeam, to produce higher quality, more durable fabric products.

Laser cutting is a versatile fabrication process that can cut through a wide variety of substrates, including metals, plastics, wood, paper, fabric, and organic material. It produces intricate designs with precision and accuracy and superior cut edges that require little to no finishing work. Overall, it allows manufacturers to provide their customers with low cost, high quality products.

For assistance with your next laser cutting or engraving project, contact us or request a free quote today.

Accubeam Laser Cutting provides services to a wide network of industries and markets. Accubeam is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.

We categorize the type of Laser Cutting by the types of materials we process; Metals, Plastics & Synthetics, Wood & Paper and Organics & Fabrics. Each material type utilized a slightly different approach and may serve different industries.

Click on the Material Type section below to view capabilities and specifications of Accubeam Laser Cutting Services.

Laser Cutting Metal

Laser Cutting Plastic & Synthetics

Mylar (PET), Acrylic, Delrin, ABS, PE, PP, Olephins,

Mylar (PET), Acrylic, Delrin, ABS, PE, PP, Olephins,Polyimide, Polycarbonate, Polyester, Polystyrene, Polyurethane

Urethanes, Aramid, Nylon

Flexible Circuits – Polyester & Polyimide (Kapton)

Fiberglass, Phenolic & Solid Surface Material (Corian)

Kevlar, Polyester Fabrics & Velcro

Aerospace – Insulation, reflective wraps

Laser Cutting Wood & Paper

Laser Cutting Organics & Fabrics

![]()

Laser cutting is a fabrication process that uses a high-focused laser to cut lines or produce holes through a workpiece. The process produces precise shapes and designs with minimal material waste and tolerances as tight as 0.002 inch on a wide range of materials, including:

During the laser cutting process, the laser beam melts through the material and uses an assist gas, such as oxygen or nitrogen, to blow molten material away from the cut—i.e., the kerf. It can be used to cut through single or multiple layers of substrates with cuts of different thicknesses.

Depending on the type and thickness of the substrate, fabricators employ several different types of laser cutting—including flame cutting, fusion cutting, and sublimation—to create high quality, precision products.