For many laser marking and laser engraving jobs we process, the requirements are straight forward. However, there are a lot of jobs that require multiple processing types. As we have described on the Laser Marking and Laser Engraving pages, there are different types of processes and flexibility within process types to drive a different result. For example, a customer’s need might require laser cutting, laser ablation and annealing, to get at the correct end result. Having the ability to run these types of jobs requires a diverse line of equipment, skill and experience to do it correctly and efficiently to maintain acceptable price points for our customer.

A recent example of where this applies is pictured here. This is an anodized aluminum AR Lower where the engraving called for a 2 tone color affect. For this job there are 2 different process types being deployed. A Laser Engraving process called ‘Laser Ablation’ is used to vaporize away the black anodized layer and expose the aluminum. This is followed by a Laser Marking process called ‘Foaming’ which alters the color of the exposed surface material. For this item 2 different parameters were used to alter the aluminum into a brighter white and darker color for the 2 tone affect.

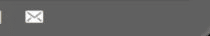

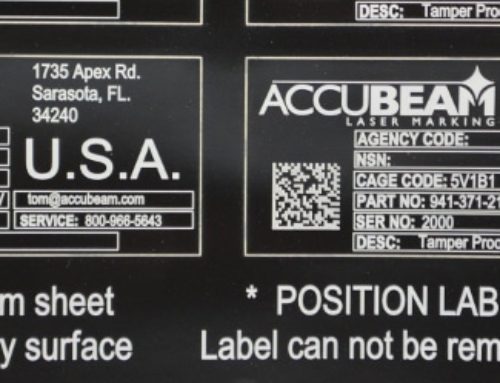

If you have unique laser engraving and marking needs, Accubeam Laser Marking has the equipment, skill and expertise to get it done. Contact us today for more information and pricing.